Products & Services

Sputtering

Sputtering technique

Sputtering is a technique for forming high-quality thin films

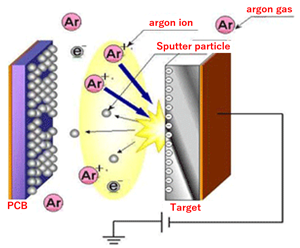

Sputtering is a kind of dry plating. A target of the thin-film forming (deposition) material and a substrate as an anode are placed in a vacuum chamber filled with inert gas (Ar gas etc.). A high voltage is applied between them.

The high voltage generates plasma and in the plasma, Ar+ collides with the target at high speed. The target particles which have been sputtered, adhere to the substrate, leading to film formation.

• The attachment energy of the deposition material is so high that it can form a film with high adhesion strength.

• Precision film thickness control is possible, resulting in a thin film with excellent density and uniformity.

• Sputtering can form a metal film with a high melting point, which is difficult by vapor deposition, and also can form a film without changing the composition of the alloy.

• Single-element metals, alloy materials, oxides, nitrides, etc. can be formed on the surface of films, resin molded products, metals, glasses, etc. with a nanoorder thickness.

Difference between Sputtering and Vapor deposition

| Deposition method | |

|---|---|

| Sputtering | By hitting argon ions against thin-film forming (deposition) metal, metal oxide, etc., the fine particles which have been sputtered adhere to the substrate and deposit on the surface. |

| Vapor deposition |

| Film adhesion | Thin film density | Alloy deposition | Deposition on heat-sensitive substrates | Deposition rate | |

|---|---|---|---|---|---|

| Sputtering | ◎ | ◎ | ◎ | ◎ | △ |

| Vapor deposition | ○ | ○ | △ | △ | ○ |

Deposition Materials and Functions

| Classification | Materials | Functions |

|---|---|---|

| Metal | SUS | Corrosion resistance, antibacterial, decorative, antistatic |

| Cu, Cu alloy | Conductive, electromagnetic shielding, antibacterial | |

| Ti | Heat retention and shielding | |

| Ag alloy | Ray reflection film, electromagnetic wave shield | |

| Cr | Corrosion resistance | |

| Metal Oxide | SiO2 | Gas barrier film, insulating film |

| ITO | Transparent conductivity | |

| TiO2 | Photocatalyst, hydrophilic | |

| Carbon | Graphite | Highly thermally conductive, conductive |

| DLC | Sliding properties, high hardness, gas adsorption | |

| Laminated films | High-refractive index material/Ag alloy/High-refractive index material | Heat ray reflection, thermal insulation |

| Low-refractive index material/High-refractive index material/Low refractive index material etc. | Anti-reflective film | |

| SiO2/ITO | Transparent electrode |

Substrate Materials

| Substrate | Materials |

|---|---|

| Resin | PET、PC、PA、PPS、PMMA、PI、PE、PEN、ABS |

| Other | Glass, ceramics |

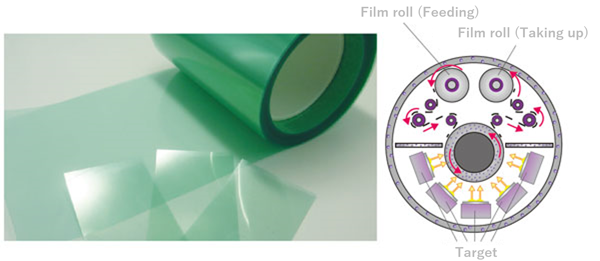

Prototyping and Mass production of Functional Films

• A wide range of base material widths up to 1600 mm are available.

• Our plant is equipped for prototyping, small lots and mass production, capable of deposition length up to 2500 m (t:125 μm).

Prototype Deposition on 3D molded products, Glass, etc., and Mass Production

• Base materials up to 1 m × 2 m are available.

• Please contact us for special cases, such as film formation on non-flat surfaces, side faces of base materials, curved surfaces and protruding objects.